Care Instructions

─ What are the stubborn stains that occur in food manufacturing sites? ─

Occurs in food manufacturing sites

What is stubborn dirt?

Food processing factories produce a wide variety of foods every day, and among these, the sweets manufacturing process in particular uses ingredients that are high in sugar and oil, such as chocolate, jam, and cream, which can easily cause dirt to stick to the conveyor belt and become very stubborn. Leaving this dirt unattended not only increases hygiene risks, but can also lead to a decline in the quality of the products themselves.

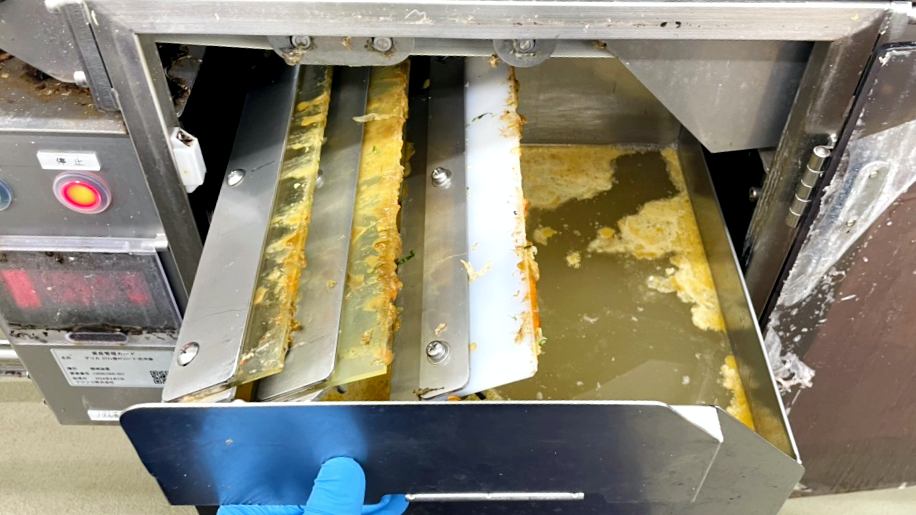

In the manufacturing of sweets, stains containing a variety of ingredients, including lipids, proteins, sugars, and carbohydrates, are generated. Particularly troublesome are stains from powders such as sugar, flour, cornstarch, chocolate, and cocoa powder, as well as viscous, oily ingredients such as fresh cream, egg yolk, vegetable oil, starch syrup, and caramel. These stains are difficult to remove once they adhere, and become even more difficult as they dry over time. Starch syrup, chocolate, sugar, and cocoa powder, in particular, tend to stick to conveyor belts and equipment, making them stubborn stains that are difficult to remove with regular cleaning.

This page will introduce how to effectively use Amber to deal with the troublesome stains that come with sweets manufacturing. From daily cleaning to regular maintenance, cleaning with Amber will improve the hygiene level in your factory and maintain a safe, high-quality manufacturing environment.

─お手入れ方法─

STEP 1

Before starting production, check that the conveyor belt surface is clean before operating the Amber.

STEP 2

Starch syrup, sugar, chocolate, powder, etc. will leave crayon-like clumps of dirt on the scraper, which will then accumulate on the belt surface.

STEP 3

Rinse the scraper box with warm water every few hours and wipe off any dirt on the belt surface with a nonwoven cloth soaked in warm water. Remove the scraper box after each run and wash it. Also, remove and wash the load rollers when they become dirty.

STEP 4

After making sure that the surface of the conveyor belt and the scraper are clean, operate the Amber and run it for 2-3 idle revolutions to keep the conveyor belt clean.

STEP ⑤

The effectiveness of Amber can only be maximized if Bell Wash is sprayed correctly. Clean the area around the spray nozzle regularly and carefully.