Customer testimonials

Thanks to you, the number of companies adopting our service will soon exceed 100!

.png)

Reasons for introducing Amber

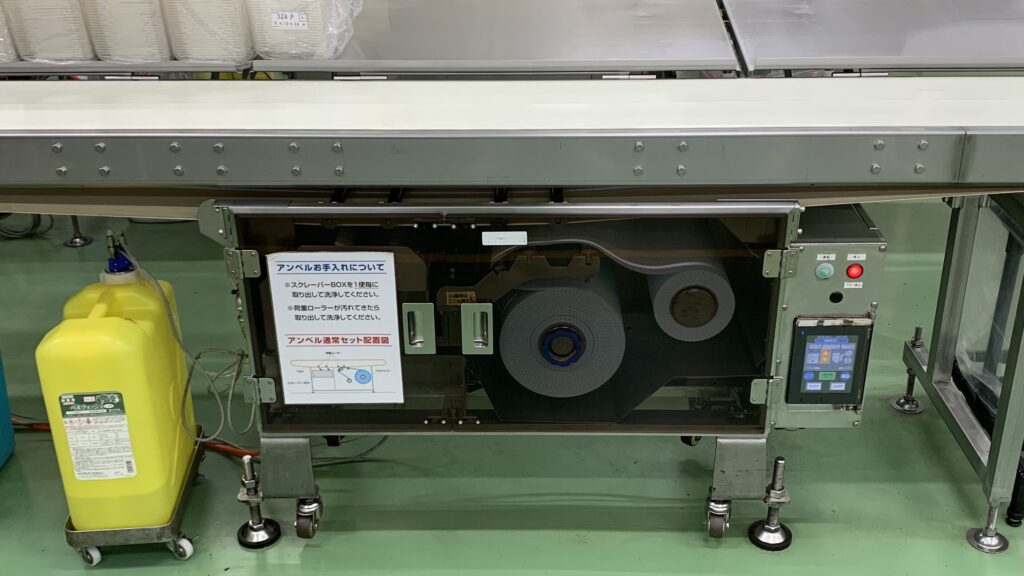

I learned about Ambel at the Bunshi Japan exhibition booth. At the time, we were having trouble with stains from corn grits that were being produced for muffins placed directly on the conveyor belt. We thought that introducing Ambel would solve the staining problem and reduce the cleaning time when changing products, which would lead to improved productivity. We conducted a demonstration test at the factory and were able to verify the expected results, so in 2013 we introduced Ambel to the factory with the muffin production line.

Effects and changes after introducing Amber

Due to the impact of the mandatory HACCP system, customers (wholesalers) are increasingly requesting measures to prevent allergen contamination. Furthermore, in recent years, an increasing number of consumers have become stricter about food hygiene management. In this environment, the introduction of Ambel has been highly praised by customers as a measure to prevent allergen contamination, and quality assurance personnel in particular have shown strong interest in Ambel. Naturally, our in-house allergen contamination tests and bacterial tests have also produced results that meet the standards.

-1024x576.png)

Reasons for introducing Amber

Effects and changes after introducing Amber

Reasons for introducing Amber

Effects and changes after introducing Amber

Reasons for introducing Amber

Effects and changes after introducing Amber

Reasons for introducing Amber

Effects and changes after introducing Amber

Reasons for introducing Amber

Effects and changes after introducing Amber

Reasons for introducing Amber

Effects and changes after introducing Amber