Disinfection effect test

Proven by sterilization test

Overwhelming sterilization power that removes over 99% of live bacteria on the belt surface

Overview of the disinfection effect test

| Installation conditions | 1 rotation (cycle) ≒ 1 minute |

| Conveyor Size | W350mm × L5m (1 piece) |

| Belt movement speed | 5m/1 minute (low speed) |

| Measurement point | Belt surface |

| Sample collection method | Swab method |

| Bacteria testing method | Standard agar plate method |

| Bacterial culture conditions | 35℃ x 48 hours |

Overview of the model experiment

In a functional test of the belt sterilization cleaning device, the surface of a conveyor belt contaminated with food ingredients was wiped and inspected, and the effectiveness of removing contaminants was evaluated based on the remaining values of hygiene indicator bacteria (general viable bacteria and coliform bacteria).

Ingredient selection

Preliminary tests were conducted to ensure that there were enough bacteria to detect general live bacteria and to minimize the variation in the number of bacteria in the samples collected, and so "beef innards" drippings were selected as the food material that would contaminate the belt surface.

Disinfection effect test results

- This experiment, which was conducted assuming contamination on a belt conveyor, established a practical sterilization control system that is extremely effective in uniformly removing contaminants adhering to the belt surface.

- By screening the special liquid agent to be sprayed on the belt surface, we were able to find a special agent that can stably control sterilization in a short period of time.

- The fabric roll wiping process has been proven to be an extremely effective process for thoroughly eliminating any traces of bacteria remaining on the belt surface.

The disinfection effect was achieved through repeated on-site improvements

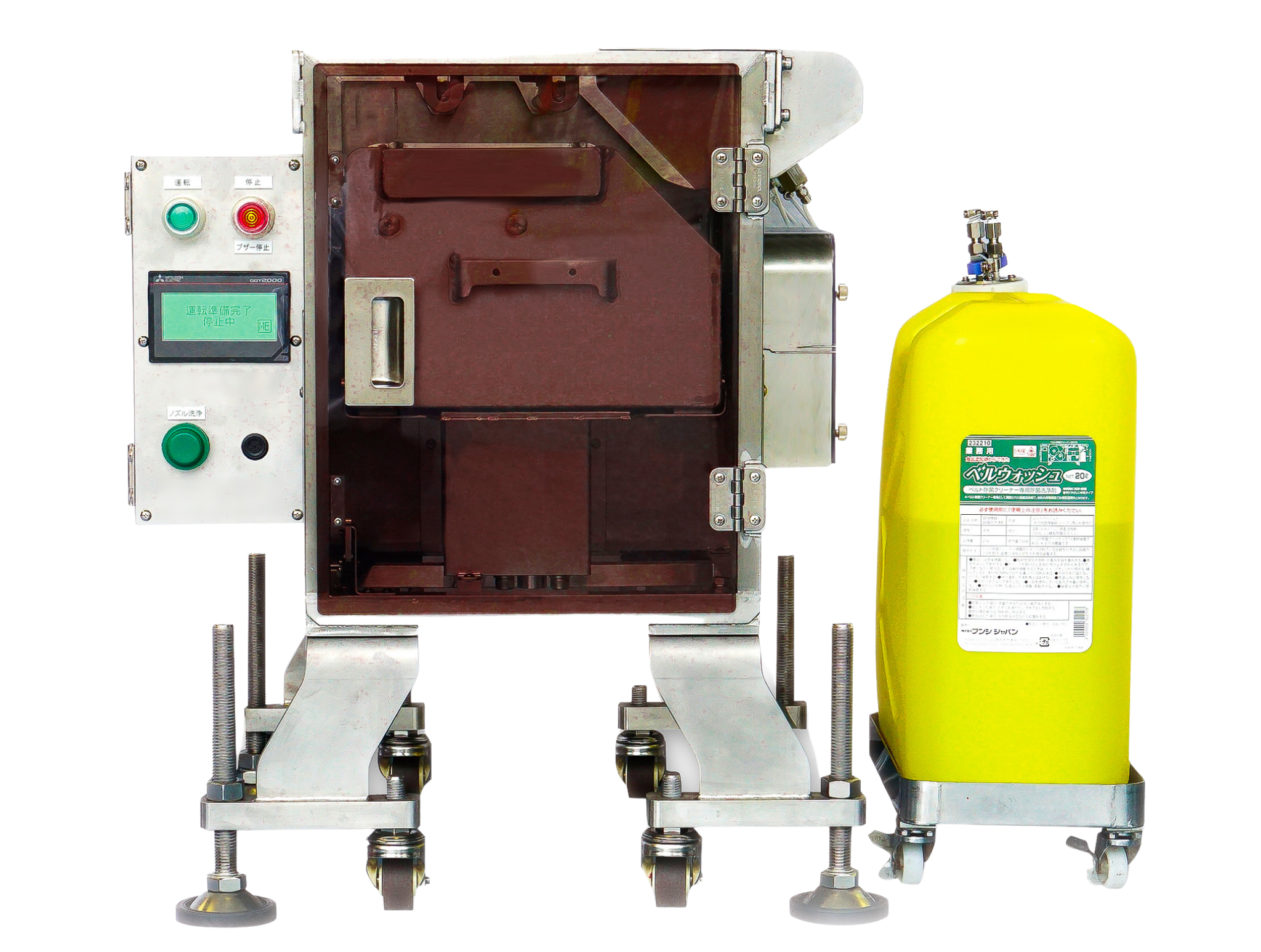

Ambel's performance is proven by sterilization effectiveness tests. Using a variety of uncooked ingredients, we repeatedly tested and improved the system to uniquely identify the optimal conditions for effective cleaning and sterilization, establishing a sterilization control system that enables stable cleaning and sterilization. Furthermore, sterilization effectiveness tests achieved a minimum value difficult to detect, showing that more than 991 TP3T of live bacteria were removed from the belt surface. Conventional conveyor belt cleaning requires manual labor after the conveyor has stopped operating, resulting in high labor costs and the risk of cross-contamination due to incomplete cleaning. However, Ambel automatically cleans conveyors while food processing and manufacturing continues, eliminating labor costs and reducing the risk of cross-contamination. This improves productivity and ensures stable profits.